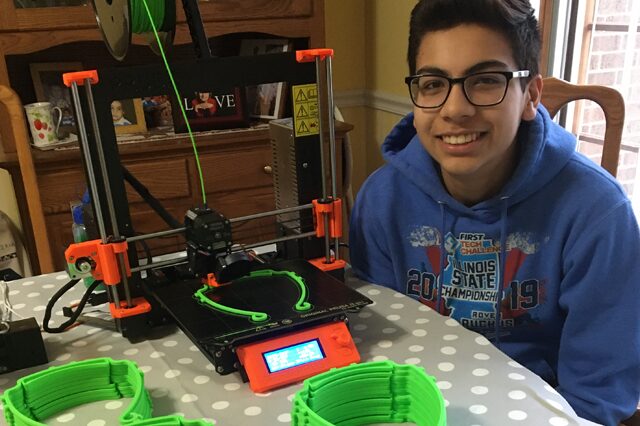

The worldwide coronavirus pandemic took so much from people over the past year. It also showed how far people will go to help others.

The face shield printing reached peak production in the summer, and then as nationwide PPE production caught up, demand for the “got robot?” masks decreased by September. As of mid-March 2021, they had distributed nearly 7,300 face shields. Although many of the face shields were used in their suburban Chicago community, some of the shields went as far as Colorado and Georgia, and some found their way to Puerto Rico and Mexico.

The reach of the shields and the impact on the community surprised Burrage.

“Originally, I thought we could get these out to some people and they would help some people, but it would kind of be something that would last for maybe a month at the most, and then they would get discarded or whatever, but they’re still in use now,” he said.

Part of the impact came from lessons learned in 4-H, such as how to work as a team and the empowerment to accomplish projects, said team mentor and Russell’s mother, Susan Russell. “It was inspiring as a mentor to see that they believe so much in what they were doing. And they’re like, ‘We can do this, we got this.’ There was no fear of the numbers. There was no fear of the amount of outreach,” she said. “It was like, a bunch of factories really pumping these things out and it was quite amazing.

”Kane County 4-H Program Coordinator Doris Braddock has watched the evolution of the “got robot?” team for several years. Along with the community service, they share their time and knowledge whether helping with robotics competitions or teaching at summer camps, she said.

“So anytime we need something in the robotics line, I feel confident I can call on these youth and they’ll step up to the challenge. Very proud of them,” she said.

The teens of “got robot?” are creating positive change in their community. Find out how you can be recognized as a changemaker by applying for the 4‑H and Invisalign® ChangeMakers Program!